Here we will cite only those that are immediately useful for design in shell and tube heat exchangers with sensible heat transfer on the shell-side. Equations for heat transfer and the pressure drop in a.

Double Pipe Heat Exchanger Design With Counterflow Or Parallel Flow Bright Hub Engineering

They are easy to repair and due to the straightforward design they are used widely in many applications and are the first choice for a.

. Number of hair pin required is estimated as following. Hairpin Heat exchangers with Multitube Finned inner Tubes From Equations 74 75 78 79 and 710 the hydraulic diameter for the Reynolds number and the pressure drop is and the equivalent diameter based on heat transfer For a double-pipe heat exchanger of length L the unfinned bare and finned areas are respectively 28. Optimization of the system cost is laborious.

The exit temperature at is 18. Tion of the problem yields the optimum values of inner pipe. Prove steady state Measure appropriate temperatur es flow rates and replicates Share raw data with classmates.

Specifically in this case we will limit ourselves to the case when the overall heat transfer coefficient is constant and the other. Geometric programming with a single degree of difficulty. Use two different methods Report the.

Hairpin Heat exchangers with Multitube Finned inner Tubes From Equations 74 75 78 79 and 710 the hydraulic diameter for the Reynolds number and the pressure drop is and the equivalent diameter based on heat transfer For a double-pipe heat exchanger of length L the unfinned bare and finned areas are respectively. 26 From Equation 1825 The total rate of heat transfer is therefore or 18. In the first case both fluids flow in the same direction.

The total heat transfer rate from the hot fluid to the cold fluid in the exchanger is expressed as. Use all data from your lab station across 5 lab sections Calculate and report overall heat transfer coefficient. Calculate Area and length of double pipe exchanger as following.

Equation 1824 can be written as where This is the temperature distribution along the pipe. Therefore pressure drop Δ pp in the length L of the inner pipe is given by 15 Δ p p f p LG p 2 2 ρ p d where fp is the friction factor for the inner pipe. Lectures 19 Applied Heat Transfer CM3110 1232019 3 T outer bulk temperature T inner bulk temperature L BUT.

Optimal design of the exchanger has been formulated as a. Flow steam through outer pipe of double-pipe heat exchanger Allow to come to steady stat e monitor. In this paper the.

Area Q U LMTD L Area π Do Compare this length with the assumed length if considerable difference is there use this length and repeat above steps till there is no change in length calculated. A double-pipe heat transfer exchanger consists of one or more pipes placed concentrically inside another pipe of a larger diameter with appropriate fittings to direct the flow from one section to the next. It is one heat.

This paper shows numerical investigations on heat transfer in a double pipe heat exchanger. DoublePipe Heat exchanger counter current cold less cold less hot hot. U is the overall heat transfer coefficient in BTUhr-ft2-oF A is the heat transfer surface area in ft2 and ΔTlm is the log mean temperature difference in oF calculated from the inlet and outlet temperatures of both fluids.

HEAT EXCHANGER ARCHITECTURE The basic structure of a double pipe heat exchanger consists of twoconcentrictubesFigure1andisusuallycommercializedin a hairpin structure Figure 2. The pressure drop in pipes can be computed from the Darcy-Weisbach equation. Double pipe heat exchange r it should be standardiz ed by calibrating different heat exchanger parameter such as Reynold number friction factor pressure drop heat transfer coefficient with.

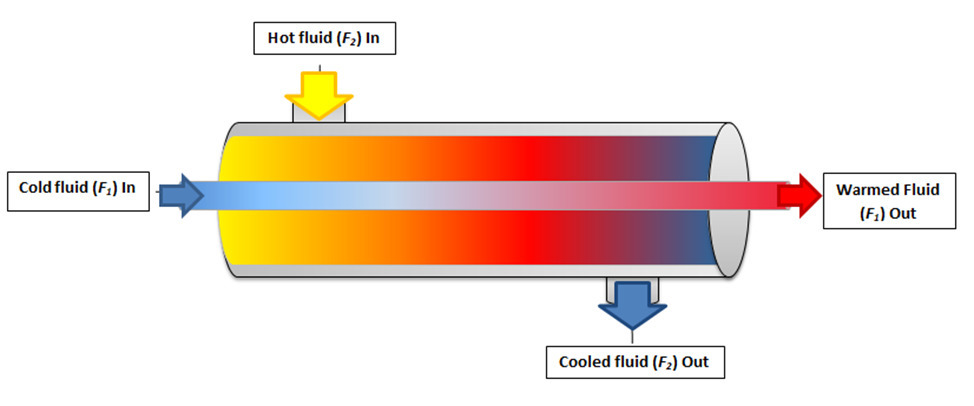

One fluid flows through the inner pipe tube side and the other flows through the annular space annulus. Double pipe heat exchanger designs are the simplest type of exchangers suitable for high temperature and pressure applications. In a concentric tube heat exchanger.

Pipe heat exchanger are available using these equations the. While the latter case attributes to ones where fluids flow in an opposite direction Fig. 25 The total heat transfer to the wall all along the pipe is 18.

T1 T2 T1 T2 x The Simplest Heat Exchanger. And ρp the mass density of the inner fluid. The temperature difference between the fluid and the wall varies along the length of the heat exchanger.

The working fluids are water and the inner and outer tube was made from carbon steel. The basic heat exchanger equations applicable to shell and tube exchangers were developed in Chapter 1. Download high-res image 43KB.

For example Figure 3 illustrates. Heat power emitted W QhρhCphT hin-Thout Heat power absorbed W QcρcCpcT cin-Tcout Properties must be evaluated separately for the cold and hot side using the average tempera- ture Heat power lost heat power emitted - heat power absorbed Efficiency η heat absorbed heat power emittedx100. If the thermal service demands a higherheattransferareaseveralhairpinscanbeinterconnected.

In double pipe heat exchangers hot and cold fluids flow mostly in concentric pipes in different configurations which are parallel and counter flows. Q UA LMTD Calculating the overall heat transfer coefficient at different operating conditions assuming to be constant throughout the exchanger using Equation. Heat exchangers are used in industrial and household processes to recover heat between two process fluids.

There are several constructions which able to transfer the.

What Is Double Pipe Heat Exchanger Types Working Principles Linquip

Configuration Of A Double Pipe Heat Exchanger The Inner Pipe Is The Download Scientific Diagram

Double Pipe Heat Exchanger Animation Heat Exchanger Animation Otosection

Parallel Flow In A Double Pipe Heat Exchanger Download Scientific Diagram

Double Tube Heat Exchanger Download Scientific Diagram

What Is A Double Pipe Heat Exchanger Working Principle Of Double Pipe Heat Exchanger

Double Pipe Heat Exchanger Parallel Flow Download Scientific Diagram

0 comments

Post a Comment